A screw compressor is a type of rotary compressor which compresses

the air due to the screw operation. The main advantage of using this compressor

is that it can supply constant air with minimum fluctuation in the distribution

pressure. It is usually applied up to 8 times for low pressure applications.

Construction of Screw Compressor

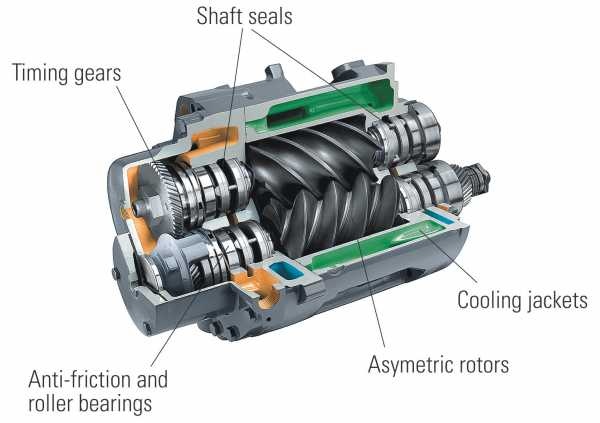

A Screw Compressor Manufacturers In India consists of two screws such as

rotating elements, one cover, one air filter, rubber seal, suction valve and

delivery valve.

Screw compressors are specially designed to handle a wide array of

dry material transfer from grainy, cement and plastic to sand, dough, lime and silicate.

Its body has two types of screws which are further known as female and male

screws. Female screws are composed of concave inlets whereas male screws are

convex.

Screw compressors work in opposite directions. This is a woman's

screw that receives driving power. On the other hand, the male screw is

responsible for transmitting power driven by the female version. It passes

through a set of so called synchronization gear.

Procedures

In addition to the major roles of male and female screws in a

compressor, there are other necessary parts of the process. While the screws

begin to rotate, the entry process happens. This is where the air fills the

inlet port, which occupies the space between the two screws.

The compression phase is next to the entry phase. This occurs when

the male thread stops or blocks the female thread. During this phase, the

rotation of the screws starts to diminish. Exhaust phase occurs as soon as the

volume reaches the compressor's delivery outlet.

Exhaust phase is an example when the screw no longer interacts

with each other. During this process, total reliability is obtained, so that

screw compressors can be of great use for many applications. Common examples

are hydraulic power system, electric motor and stable and mobile applications.

Different types and their specific applications

Rotary screw compressor is found under the type of gas compressor.

It uses a mechanism through a single screw or double-counter helical screw.

While the system does its work, the gas can be pulled through the port of the

cover, and then it is captured in a certain cave. Then the gas is discharged

for the second port in the cover. Such Screw Compressor Manufacturers In

India are planted in ordinary industries, such as diesel driven trailer

units which are seen on construction sites.

Another special type is oil-flood screw compressor. It is often

functional in sealing and cooling gas charging. As the oil flows in the

process, it passes separation from the discharge stream before being cooled and

filtered. Later, the oil is recycled.

Oil free Screw Compressor Manufacturers In India are also

examples of this industrial machinery. Without the presence of any oil, air

compression is made possible by screws. This type is relatively important in

medical research as well as in semiconductor industries.

Comments

Post a Comment