Being educated on different types of compressors and various

compressor manufacturers is an essential part of the procurement process. There

are many sources available to help you know which PET Air Compressor and compressor accessories are right for you. The first

purchase that you saw and install it is more buying process. Wrong one for your

application will give you the cost of money.

There are three basic types of such compressors. These are

rotary screw, centrifugal and reciprocal. There are different styles of each

type, including water and air cooling, single phase or multistage, and oil

flood or oil free air.

Using the literature provided by the manufacturers of

compressors will help you understand how each type works, and is essential to

making the right choices for your business. They all perform the same final

work, which is to compress the air for a high pressure, but their methods of

completing it are quite different. These differences help them to adapt to

different work environments and applications.

Compressors have two cheap choices: rotary screw and another

reciprocating compressor. Both types work on the same principle, but in

different manners. Uses a rotor to produce a high pressure air and uses a

piston, respectively. They take in a quantity of air and take it in small

amounts while making pressure.

Both are capable of output between 1 and 600 horsepower, or

more. While some of these types of oils are free air compressors, most are

oil-flooding, or lubricants. Because lubricating oil can be found in air and

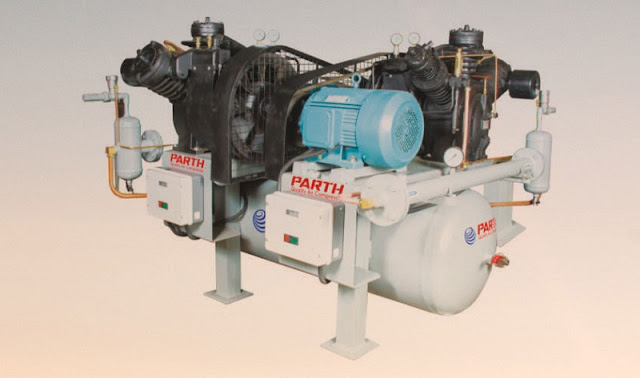

can cause problems with compressor components, most Air Compressor Manufacturers In India will have a separator with the purchase of lubricating

compressors. Both rotary screw compressors and reciprocating compressor are

inexpensive.

Centrifugal is the last type of compressor. It works like

others, but is mechanically different. It uses increased velocity to increase

air pressure rather than squeezing. The centrifugal compressor is air-cooled,

and produces oil-free air. Oil free air means that no separator is necessary.

Centrifugal compressor is considered to be very low

maintenance because it contains very little running parts and can last for long

before the need for service. Compressor manufacturers usually sell at

centrifugal Parth Air Compressor

systems at places like hospitals because clean, uncontaminated oxygen is of

great importance.

Comments

Post a Comment